To install, first torque the fitting, wait 15 to 20 seconds and retorque to manufacturer’s specification. Upon compression, the gasket changes from dead soft annealed to full hard condition it should not leak until you undo the system and put in a brand-new gasket.

Torque Tools

SECO Seals recommends utilizing torque tools when installing SECO45 conical seals. Click on the button and see the torque tools we use.

SECO45 Torque Specification Engineering Document and Download

The “SECO45 Torque Specification” PDF consists of five pages.

For detailed technical information on SECO45 torque values, you can either view the engineering drawing by clicking on an image below or download the “SECO45 Torque Specification” PDF.

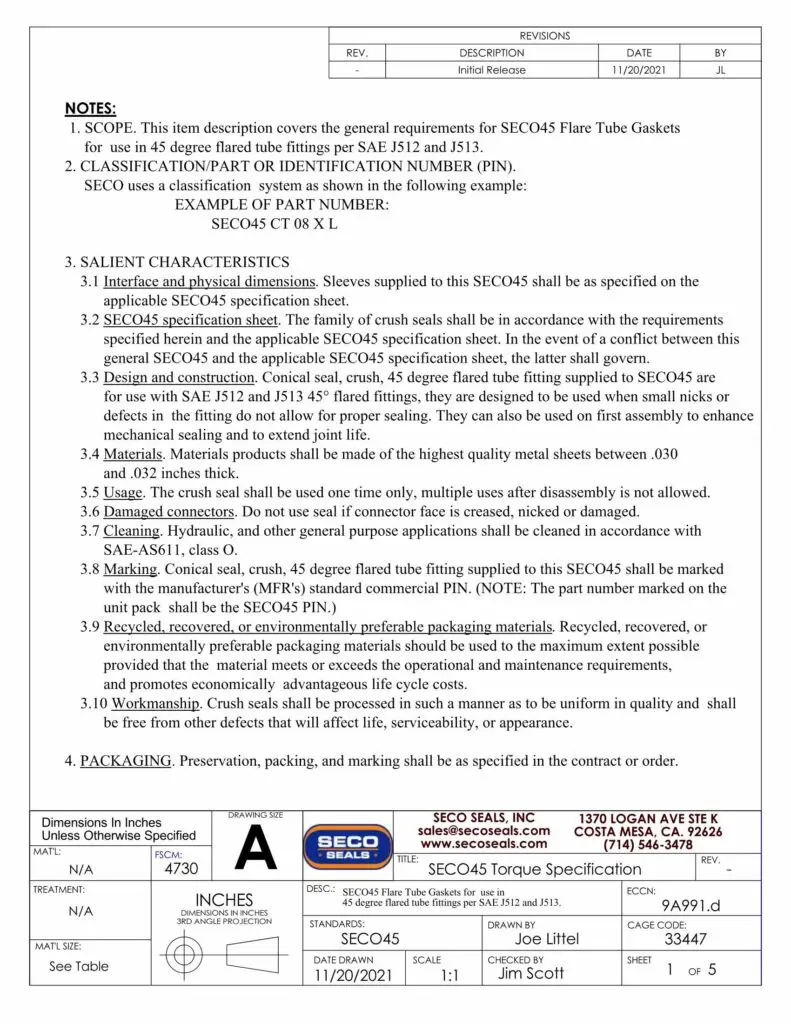

Page 1 – SECO45 Torque Spec Overview

Page 1 of the “SECO45 Torque Specification” engineering document contains the notes and describing the “SCOPE“, “CLASSIFICATION/PART or IDENTIFICATION NUMBER (PIN)“, the “SALIENT CHARACTERISTICS“, and “PACKAGING” information.

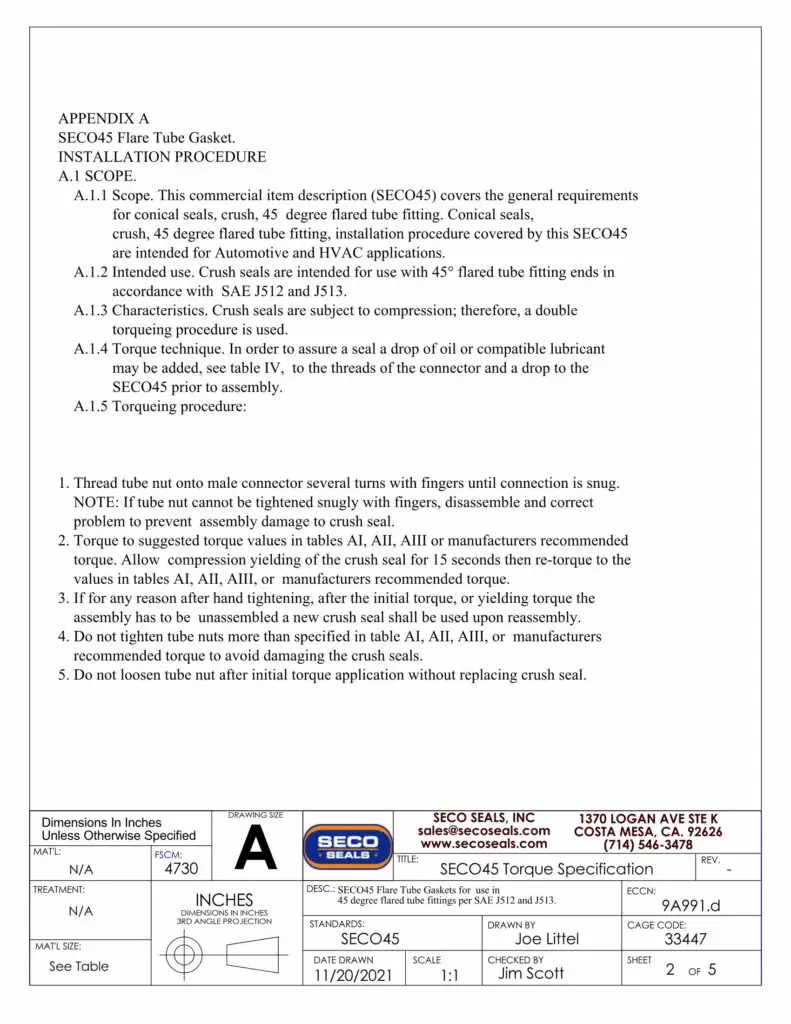

Page 2 – SECO45 Torque Spec Overview

Page 2 of the “SECO45 Torque Specification” engineering document contains “APPENDIX A, INSTALLATION PROCEDURE“.

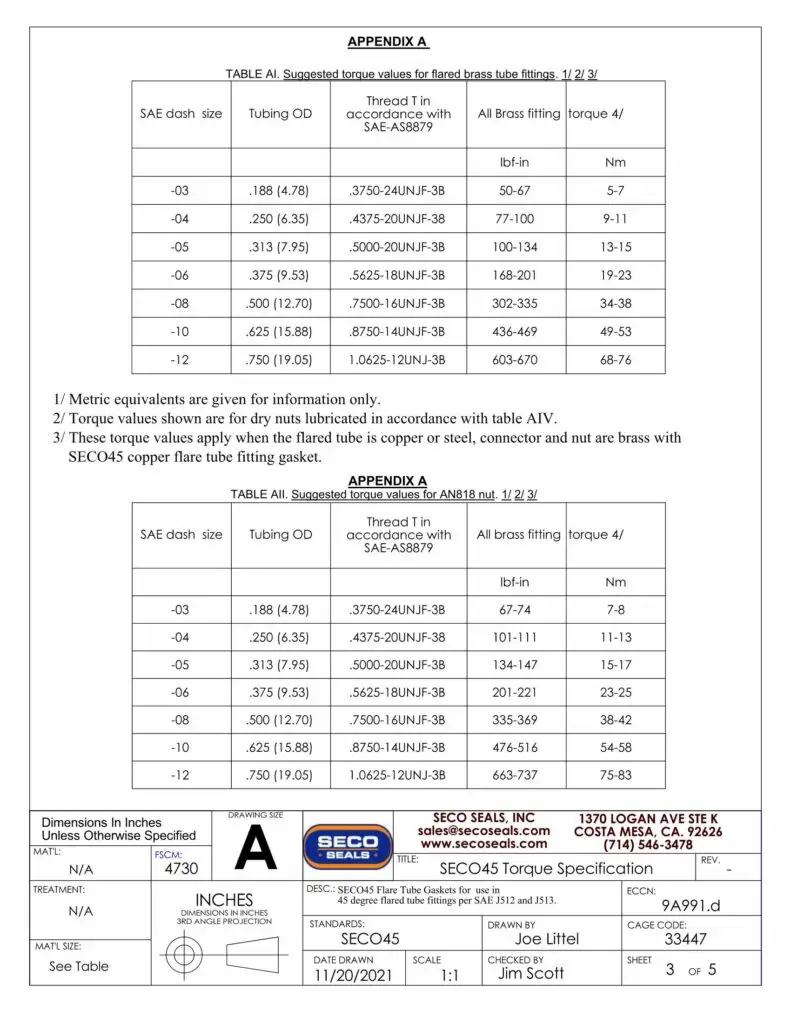

Page 3 – SECO45 Torque Spec Overview

Page 3 of the “SECO45 Torque Specification” engineering document contains “APPENDIX A, TABLE AI, Suggested torque values for flared brass tube fittings” and “TABLE AII, Suggested torque values for AN818 nut“.

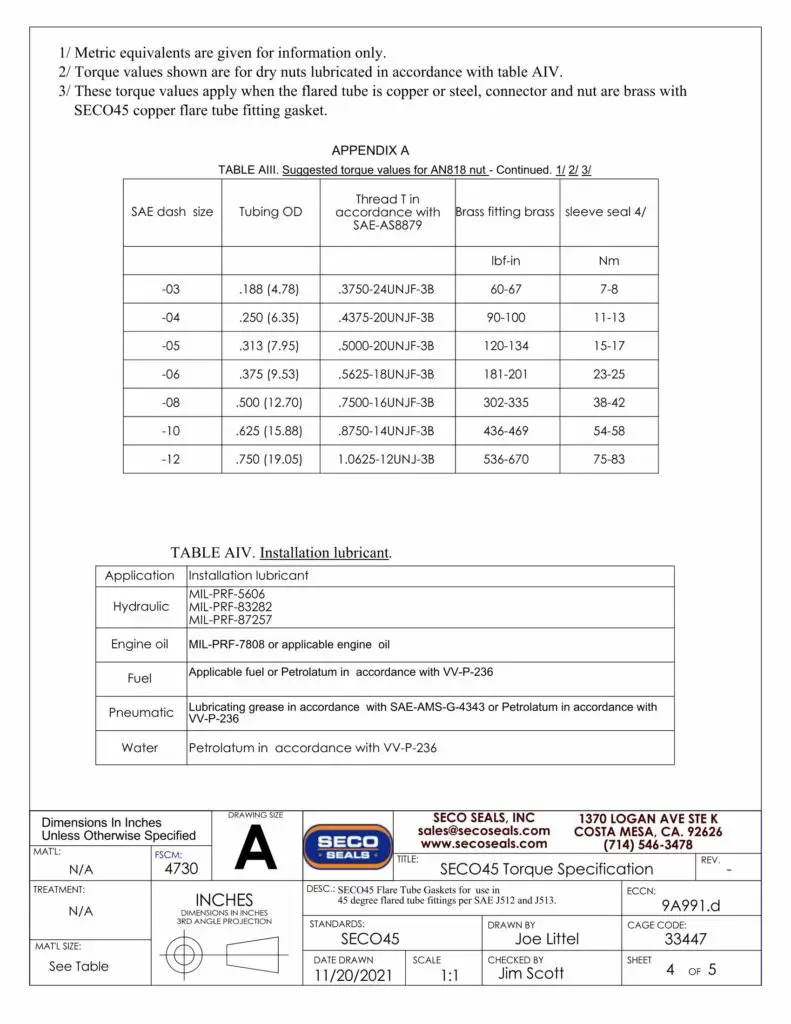

Page 4 – SECO45 Torque Spec Overview

Page 4 of the “SECO45 Torque Specification” engineering document contains “APPENDIX A, TABLE AI, Suggested torque values for AN818 nut – continued” and “TABLE AIV, Installation lubricant“.

Page 5 – SECO45 Torque Spec Overview

Page 5 of the “SECO45 Torque Specification” engineering document contains “APPENDIX A, APPLICABLE DOCUMENTS“, “DEPARTMENT OF DEFENSE SPECIFICATIONS” and “SAE INTERNATIONAL SPECIFICATIONS“.

Call or Fax for Information

Phone: +1 714.546.3478

Fax: +1 714.546.3106

or