About Us

SECO SEALS, an aerospace manufacturer of high-pressure tube fitting gaskets, is ISO 9001:2015 and AS9100D certified. We are a family-owned American small manufacturer in business since 1969. Our industry standard product line, SECO7 “37 Degree Flared Tube Fitting Conical Seals,” is renowned in the industry for its ability to prevent leaks in any environment. Our goal is to eliminate and prevent leaks caused by the failure of fittings in fluid and gas connections.

These flare gaskets (also referred to as “flaresavers” or “crushwashers”) are designed to withstand vibration, temperature changes, full vacuum, and exceed the pressure ratings of fittings. This allows the fittings to be used repeatedly by replacing the gasket after each use, improving performance and avoiding the need to replace fittings.

The ISO and AS quality certifications guarantee the highest quality and reliability, backed by our commitment to excellent customer service. We also offer build-to-print sealing solutions for extreme pressure and temperature applications made of the highest quality metal foils.

CAGE Code and ECCN

SECO SEALS CAGE (Commercial and Government Entity) Code is 33447, and the ECCN (Export Control Classification Number) is 9A991.d.

Application Environments

SECO SEALS products are used in applications for:

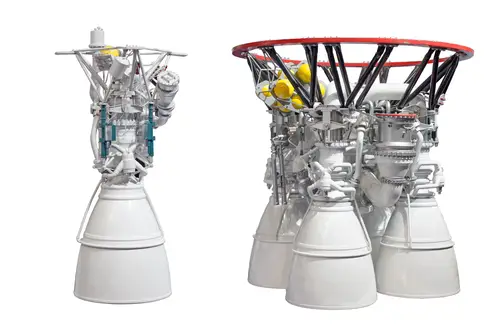

Aerospace

From the far reaches of outer space to the earth’s atmosphere, the SECO7 37-degree flared tube fitting conical seals prevent leaks from occurring.

Clean Technology

SECO7 and SECO45 flare tube fitting gaskets help mitigate leaks that impact the environment.

HVAC

SECO45 conical seals simplify installation of HVAC systems by reducing repeat service calls for leaks when properly installed.

Marine

From the surface of the ocean to the depths of the Marianna Trench, SECO SEALS products are designed for use in high-pressure applications to prevent harmful leaks in the marine environment.

Additional Application Environments

Among other areas we target are:

- Geological Services

- Petroleum Industry

- Automotive Industry (Race Cars)

Product Lines

SECO SEALS product lines include SECO7 37-Degree Flare Gaskets, SECO45 45-Degree Flare Gaskets, SECO11 24-Degree Flareless Gaskets, SECO77 Kits, and SECO5007 XYLAN 1424 coated conical seals.

Click a button for product information.

Reliable, flight grade components made in accordance with AS4824, a National Aerospace Standard.

For Freon, LP and Natural Gas, flammable liquids, instrumentation, refrigeration, power steering, HVAC, hydraulic and pneumatic systems.

Reliable, flight grade components made in accordance with AS4825, a National Aerospace Standard.

Pre-assembled SECO77 Kits with a wide assortment of our SECO7 37 Degree Flare Tube Gaskets.

Ideal for use in harsh environments such as marine, aerospace, oil and gas, and chemical processing industries

Our Goal

Our goal is the elimination and prevention of leaks caused by the mechanical failure of connections between fittings for fluids and gases in any environment.

Why Use Our Products

SECO SEALS’ flare gaskets are designed for deep space to never fail and never wear out. You put it in behind the wall and it will be there 100 years later. It is designed to expand and contract with the systems. It withstands vibration, temperature changes and full vacuum. Additionally, it may exceed the pressure ratings on your fittings. The SECO 37-degree Conical Seal has been pressure tested over 10,000 PSI on certain line sizes. Its newer cousin, the SECO45, 45-degree Conical Seal, is usually rated at over 500 PSI.

Using our flare gaskets turns the weakest link of your system into your strongest link. These gaskets allow the unlimited use of fittings by replacing the gasket after each use. The SECO flare gasket is used to protect the surface of the fitting and the flare tube. These soft annealed crush washers improve performance of the connection by custom forming into the slight imperfections of the fitting or flare surface finish.

The Problem

Repetitive opening and closing of connections for liquids and gases provide a path for leaks on sealing surfaces. These repetitive actions may eventually require the replacement of the fittings which increase both labor and material costs.

The Solution

Annealing is a heat treatment process that changes the physical and sometimes also the chemical properties of a material to increase ductility and reduce the hardness to make it more workable (malleable). Ductility is the ability of a solid material to stretch under tensile stress, i.e., when a metal is stretched into a wire.

Annealing copper or any other metal involves heating it to a specific temperature and allowing it to cool at a specified rate. This process increases the metal’s ductility, and reduces its hardness (softer, more malleable).

Make SECO SEALS Your Choice for Gasket Applications

Videos

SECO SEALS installation demonstration videos and kit videos are available in multiple languages for customer convenience.

Installation demonstration videos, torque videos, and SEC077 Kit videos in ten languages.

Inspection and correction video for out of round conical seal.

Call or Fax SECO SEALS for Information

Phone: +1 714.546.3478

Fax: + 1 714.546.3106

or