The University of Akron in Akron, Ohio, has a Akronauts Rocket Design Team. They are a student-run organization with the goal of expanding students’ knowledge outside of the classroom to propel them into the aerospace industry. The liquid propulsion team develops and tests liquid rocket engines and is in the process of designing an engine for propulsive lander applications.

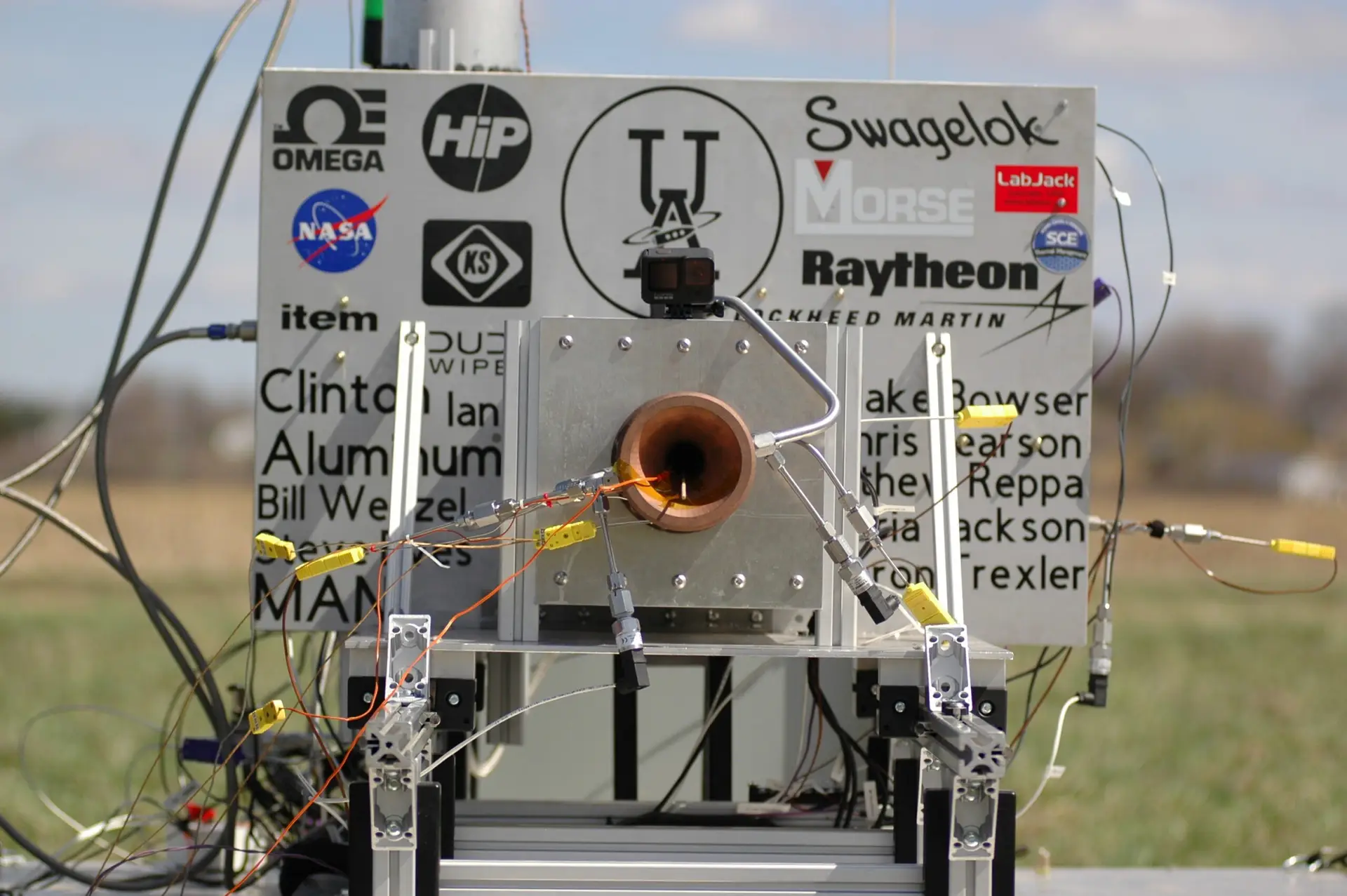

According to Project Manager Nicole Zimmerli for the Akronauts Rocket Design Team, “last year they designed a regeneratively cooled, additively manufactured liquid rocket engine. It was tested on their team-built test stand which included a feed system utilizing SECO Seals 37-degree conical gaskets. The engine was pressure-fed, used nitrous oxide and ethanol as their oxidizer and fuel, and was externally pressurized by nitrogen. This upcoming year, the team is building upon our previous learnings, and developing a feed system capable of throttling and gimbaling the engine.”